Oil-immersed Transformers

The laminated core transformer adopts high magnetic permeability and low-loss silicon steel sheets, with a stepped multi-stage joint structure. The core tensioning and clamping use anti-loosening structures. The cross-section of the transformer core is oblong, which can reduce the height of the core yoke, thereby lowering the overall core height of the transformer, saving silicon steel sheets, oil tanks and other steel materials, as well as transformer oil consumption.

Share:

General Introduction

The laminated core transformer adopts high magnetic permeability and low-loss silicon steel sheets, with a stepped multi-stage joint structure. The core tensioning and clamping use anti-loosening structures. The cross-section of the transformer core is oblong, which can reduce the height of the core yoke, thereby lowering the overall core height of the transformer, saving silicon steel sheets, oil tanks and other steel materials, as well as transformer oil consumption.

The oil tank is a corrugated rectangular tank. And the corrugated sheets are automatically welded by robots, ensuring full, smooth, flat and uniformly thick weld seams to prevent oil leakage. The elasticity of the corrugated sheets can compensate for the volume change of transformer oil caused by temperature variations.

Typical Applications

①High-voltage power transmission networks ;

②Large industrial loads (e.g., high-voltage power transformers in steel plants and aluminum smelters, which need to withstand impact loads);

③Outdoor public substations (cost-sensitive areas with diverse capacity requirements).

Advantages

Except for small-capacity models that use copper conductors, low-voltage windings generally adopt a cylindrical structure with copper foil wound around the shaft. High-voltage windings use a multi-layer cylindrical structure, which ensures balanced ampere-turn distribution of the windings, low leakage flux, high mechanical strength and strong short-circuit resistance.

By replacing the oil conservator with corrugated sheets, the transformer oil is isolated from the outside environment. This effectively prevents the entry of oxygen and moisture, which would otherwise degrade insulation performance, and extends the service life of the transformer.

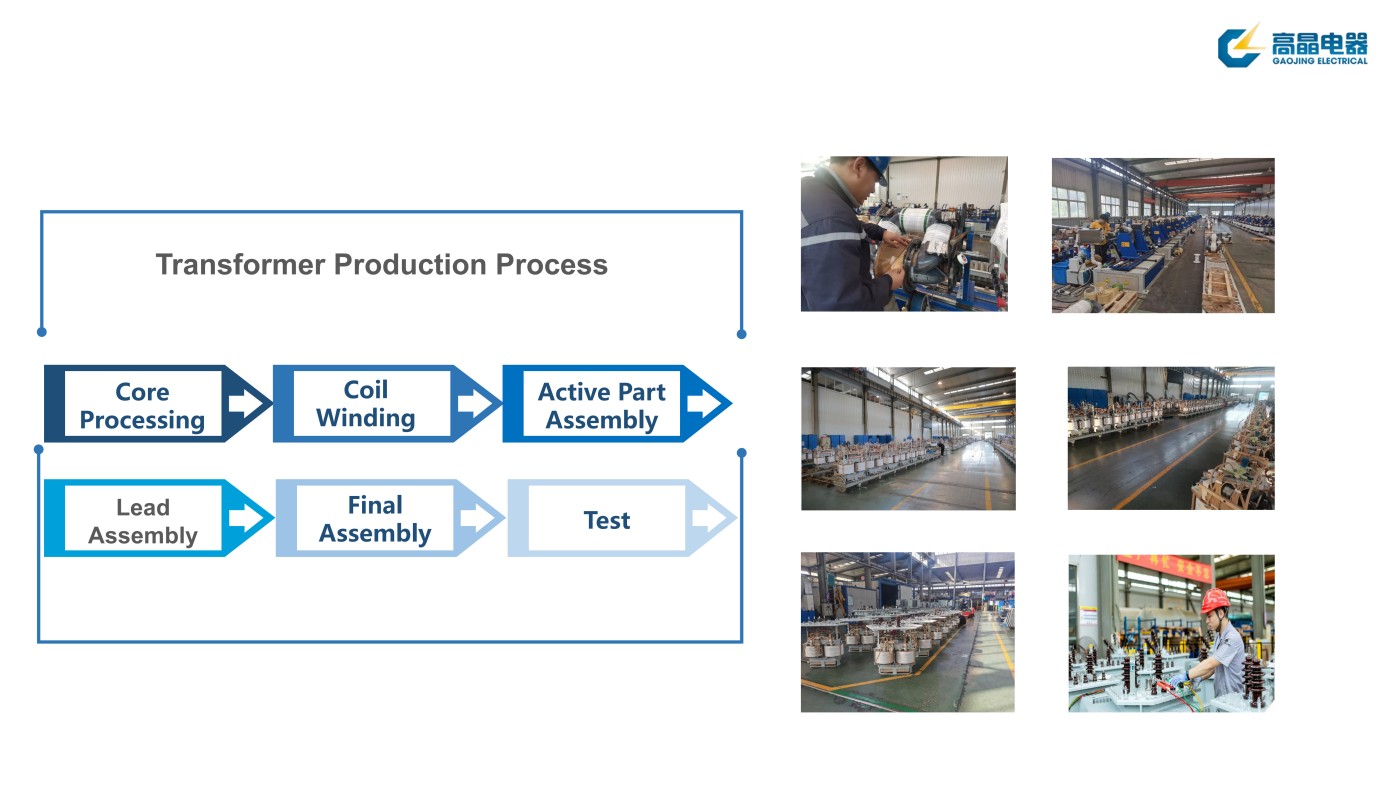

Production Process

Customization Range

①Capacity: 30kVA-50000kVA;

②Voltage Level: 10kV-110kV ;

③Core Material: Ordinary silicon steel sheets or high-grade silicon steel sheets ;

④Special Customization: Enhanced short-circuit resistance, low-temperature environment adaptation .

Require More Customized Solutions?

We offer customization to meet your specific needs. Our expert team will collaborate with you to develop the perfect product for you

Related Products

Three-Phase Oil-Immersed Silicon Steel Tridimensional Toroidal Core Transformer

The three-phase oil-immersed silicon steel tridimensional toroidal core transformer is an innovative energy-saving power transformer. By reforming the laminated magnetic circuit structure and three-phase layout of traditional power transformers, it achieves optimized product performance.

Three-Phase Oil-Immersed Amorphous Alloy Tridimensional Toroidal Core Transformer

The SH-RL series amorphous alloy tridimensional toroidal core transformer features a core made of amorphous alloy strips as the main component, and a three-phase closed tridimensional toroidal core structure.

Products

Contact Us

Tel: +86 188 3000 9955

E-mail: gjscb@hbgjdq.com

WeChat: zjj9232013

Add.: No.118, Luchan Road, Yongnian District, Handan City, Hebei Province, China

Send in Inquiry

Send in Inquiry