Dry-type Transformers

The core of the SCB series laminated core dry-type transformer adopts a core-type structure, typically a three-phase three-limb design. Since the magnetic domains of high-permeability cold-rolled silicon steel sheets are directional—with optimal magnetic conductivity along the direction of the magnetic domains and the poorest magnetic conductivity perpendicular to them—the connection between core limbs and yokes usually adopts a 45° fully mitered joint. To reduce local overheating caused by uneven magnetic density at the joints and excessive iron loss, a multi-step interleaved lamination method is generally adopted.

Share:

General Introduction

The core of the SCB series laminated core dry-type transformer adopts a core-type structure, typically a three-phase three-limb design. Since the magnetic domains of high-permeability cold-rolled silicon steel sheets are directional—with optimal magnetic conductivity along the direction of the magnetic domains and the poorest magnetic conductivity perpendicular to them—the connection between core limbs and yokes usually adopts a 45° fully mitered joint. To reduce local overheating caused by uneven magnetic density at the joints and excessive iron loss, a multi-step interleaved lamination method is generally adopted.

Typical Applications

Industrial scenarios sensitive to cost and with large load fluctuations: such as machinery processing plants, metallurgical workshops, and chemical plants, which are suitable for impact loads such as machine tools and motors.

General power distribution fields: such as commercial complexes, ordinary office buildings, and municipal facilities (street lamp power distribution), which only need to meet basic power supply requirements.

Advantages

Both high-voltage and low-voltage windings are layer-type windings wound with conductors.

The high-voltage winding typically adopts a segmented cylindrical structure, while the low-voltage winding is a multi-layer cylindrical structure made of copper foil.

The windings are manufactured using a vacuum casting process, offering energy efficiency, environmental friendliness, moisture resistance, corrosion resistance, and strong short-circuit withstand capability.

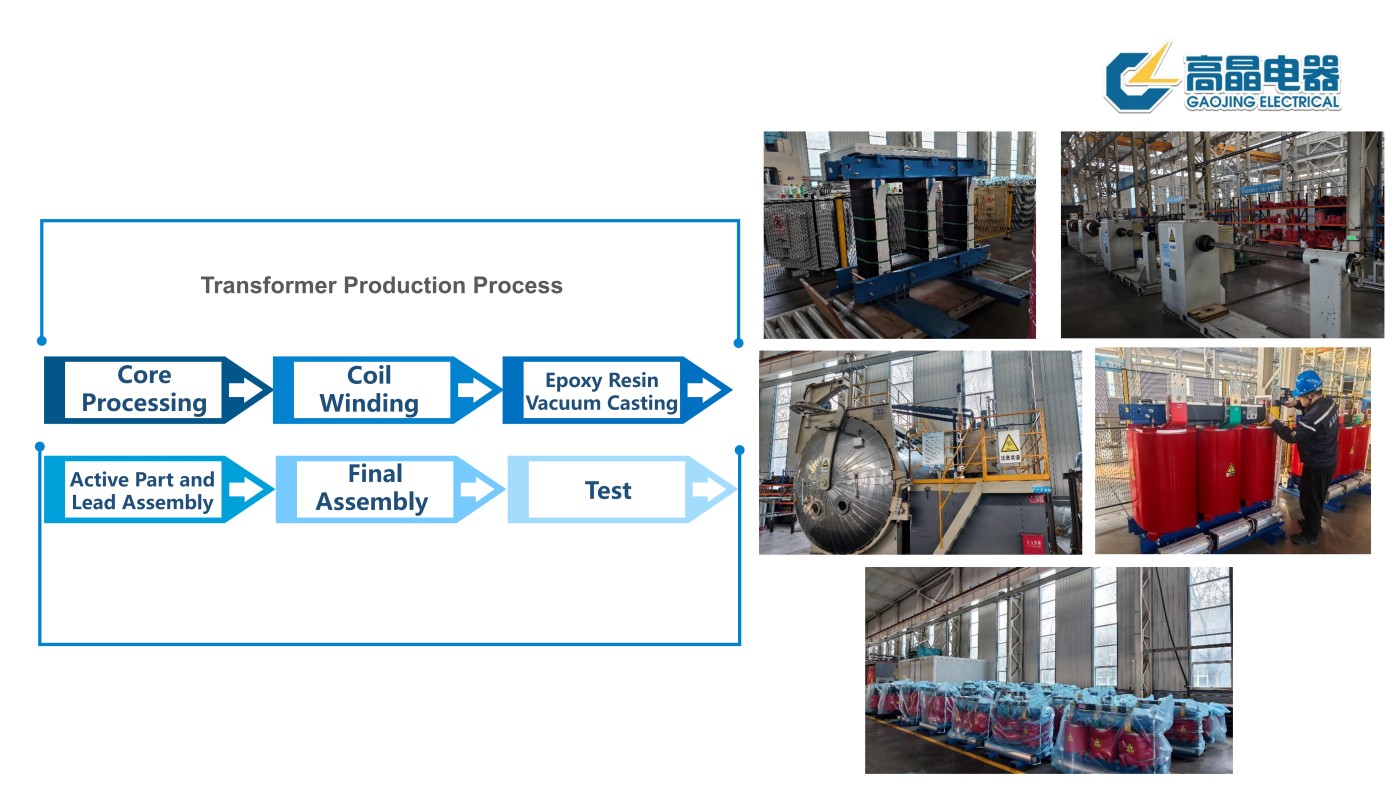

Production Process

Customization Range

①Capacity: 50kVA-5000kVA .

②Voltage Level: 10kV-35kV.

③Core Material: Silicon steel sheets or high-magnetic-induction silicon steel sheets.

④Protection Level: Can be customized according to customer requirements.

Require More Customized Solutions?

We offer customization to meet your specific needs. Our expert team will collaborate with you to develop the perfect product for you

Related Products

Three-Phase Dry-Type Silicon Steel Tridimensional Toroidal Core Transformer (SCB-RL Series)

The SCB-RL series resin-insulated tridimensional toroidal core dry-type transformer adopts a tridimensional toroidal core as its key component, achieving perfect symmetry in the three-phase magnetic circuit.

Three-Phase Dry-Type Amorphous Alloy Tridimensional Toroidal Core Transformer

The SCBH-RL series amorphous alloy tridimensional toroidal core dry-type transformer features an innovative tridimensional toroidal core design.

Products

Contact Us

Tel: +86 188 3000 9955

E-mail: gjscb@hbgjdq.com

WeChat: zjj9232013

Add.: No.118, Luchan Road, Yongnian District, Handan City, Hebei Province, China

Send in Inquiry

Send in Inquiry